Active Heave Compensation: Frequently Asked Questions (FAQ)

1. What is Active Heave Compensation?

Active Heave Compensation (AHC) is an advanced technology that stabilizes offshore and subsea operations by counteracting vessel motion caused by waves. Using sensors and real-time control systems, AHC ensures precision and safety in challenging conditions, reducing downtime and improving efficiency. Scantrol is an industry leader in AHC solutions, offering innovative systems like the off-the shelf mTrack AHC Controller with integrated MRU.

A visual explanation of how Active Heave Compensation (AHC) works.

2. What is an AHC Crane?

An AHC crane is a specialized crane equipped with active heave compensation technology. These cranes keep their load stable by controlling their crane in real time to counteract vessel motion. Scantrol’s AHC controller mTrack with a built-in Motion Reference Unit (MRU) makes integrating this advantage into smaller offshore cranes affordable, enhancing their performance in subsea lifting and intervention operations.

→ Learn more about AHC for Offshore Cranes

3. What is heave in Drilling?

Heave refers to the vertical motion of a vessel caused by waves, which can disrupt drilling operations by affecting bit weight and displacement. Scantrol AHC maintains precision during drilling, particularly in varying sea conditions.

→ Learn more about AHC for Drilling

AHC can be retrofitted to a PHC cylinder system by adding one or two active cylinders in parallel with the passive cylinders, along with mTrack AHC Controller, hydraulic powerpack, and control valves. This setup improves system stability by up to 95% without altering the basic operation of the PHC system.

→ Learn more about adding AHC to your PHC

4. What is Heave Compensator?

A heave compensator is a device that mitigates the effects of vessel movement caused by waves. These systems are used to dynamically stabilize operations enabling safer and more efficient offshore activities like lifting, drilling, or subsea construction.

5. What does heave do in offshore engineering?

Heave impacts the stability of vessels and equipment, leading to operational inefficiencies and safety risks during tasks like ROV operations, crane lifts, and subsea construction. Heave compensation systems, particularly AHC, address these challenges by reducing motion disruptions and ensuring operational stability.

→ Learn more about Active Heave Compensation for ROV Operations.

6. How is Heave Calculated?

Heave is calculated using motion reference units (MRU’s) that measure vessel displacement and velocity. Theis data is processed by an AHC controller, which controls winches or cylinders to counteract motion in real time.

→ Learn more about mTrack AHC Controller with Integrated MRU

7. What is the differences between heave and hoist?

Heave refers to the up-and-down motion of a vessel caused by waves at sea. Hoist, on the other hand, involves raising or lowering objects using equipment like cranes or winches. mTrack Active Heave Compensation controller synchronizes these, keeping the hoist steady unaffected by vessel movement.

→ Learn more about mTrack AHC Controller with Integrated MRU

8. What is the difference between settlement and heave?

Settlement is the downward movement of ground or structures over time due to natural forces. Heave, in offshore contexts, refers to upward or wave-induced vertical motion of vessels. While they occur in different settings, both impact structural stability.

→ Learn more about Heave Compensation

9. What is the difference between active and passive heave compensation?

Active heave compensation (AHC) uses real-time sensors and an advanced controller, such as the mTrack AHC Controller, to counteract vessel motion by dynamically controlling lifting equipment on a vessel. This results in precise, stable operations even in rough conditions. Passive heave compensation (PHC), on the other hand, relies on mechanical systems like springs or hydraulic cylinders to dampen motion. PHC is only effective with large loads or while connected to a fixed structure, while AHC has a higher precision when operating in the water column, and works independently of load size and shape.

10. How does the complexity and cost of AHC compare to PHC?

Active heave compensation (AHC) was traditionally more complex and expensive than passive heave compensation (PHC). However, with advancements like the mTrack AHC Controller, AHC systems are now easier to configure, test, and tune independently, significantly reducing complexity and cost while maintaining superior performance.

→ Learn more about mTrack AHC Controller

11. What is the difference between constant tension and active heave compensation?

Constant tension systems maintain a steady pulling force on a line or load, regardless of vessel movement, to prevent slack or over-tension. Active heave compensation (AHC), on the other hand, dynamically adjusts the load’s position using sensors and motors to counteract vessel heave, ensuring precise stability and control during operations. Constant tension relies heavily on the size and shape of the lifted load, while AHC has a higher precision when operating in the water column, and works independently of load size and shape.

→ Learn more about Scantrol AHC

12 Can Active Heave Compensation (AHC) be added to a Passive Heave Compensation (PHC) cylinder system?

13. How do I know if my winch is capable of AHC?

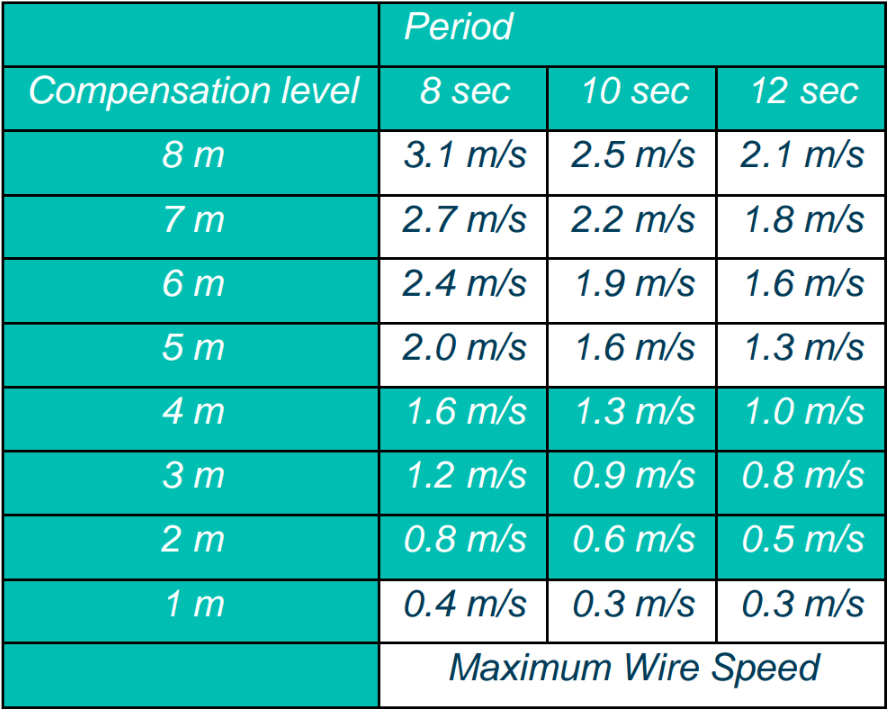

The line speed of the winch is normally the limiting factor for AHC operation, and the maximum line speed determines the compensation level that can be achieved. If your winch has a maximum line speed in the range of 50 to 80 m/min, it will be possible to compensate for 3 – 4 m vessel motion, which is sufficient for most AHC applications.

-> Get a free AHC analysis to determine if your winch is capable of AHC

14. How do I find the AHC capacity of an existing winch?

The Scantrol AHC Analyzer tool can assist you when designing an AHC winch, or help you to find the AHC capacity of an existing winch. We can provide either a quick analysis using the main parameters of the winch or an in-depth analysis including all of the winch design parameters.

-> Get a free AHC analysis to determine the AHC capacity of your winch

15. Why Choose Scantrol for Heave Compensation?

Scantrol’s mTrack AHC Controller offers a proven, cost-effective solution for Active Heave Compensation that’s easy for your team to manage without hiring expensive experts. With free training, pre-defined AHC apps, and an integrated Motion Reference Unit (MRU), mTrack simplifies setup, reduces costs, and ensures precise, reliable performance

→ Learn more about the benefits of Scantrol AHC