How to Retrofit mTrack to Existing Winches

mTrack is the easiest way to get AHC functionality on winches used for subsea operations.

It is simple to install mTrack as an add-on to the standard control system supplied with the winch, and the built-in AHC toolbox makes it is possible to do all testing and tuning at the dockside.

Many existing winches and cranes can be easily converted to AHC, and we have a large number of customers who have realized significant cost savings and reduced time by retrofitting Scantrol AHC.

mTrack can be delivered as a turn-key solution.

The upgrades can be completed on the vessel or in your yard without the need for specialists on-site.

Scantrol AHC is installed on new and upgraded winches from a range of recognized crane and winch manufacturers.

Get in touch with Scantrol to learn more about how to integrate mTrack.

Winch requirements for AHC Operation

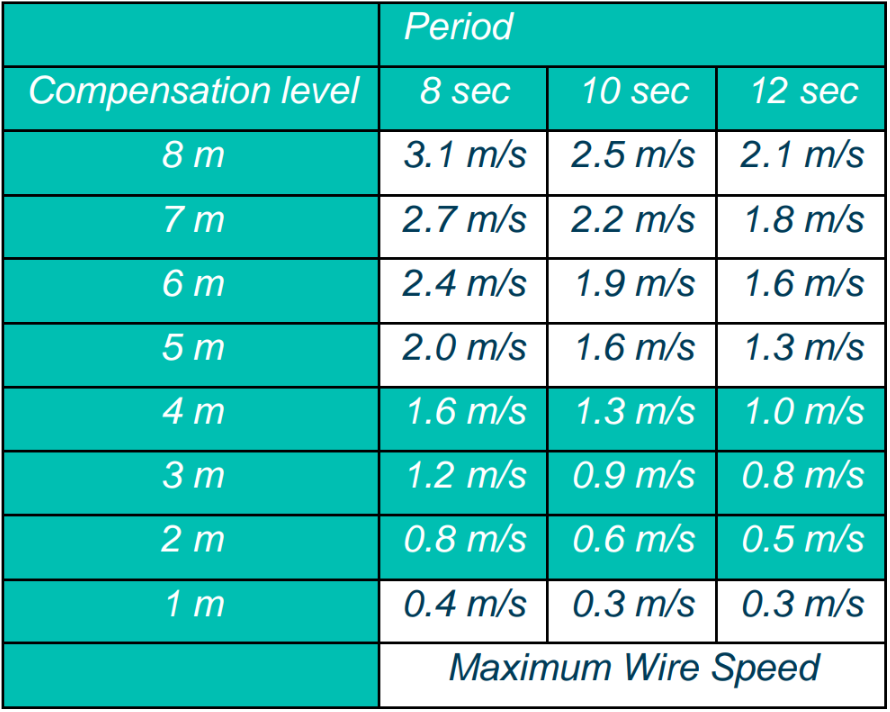

The line speed of the winch is normally the limiting factor for AHC operation, and the maximum line speed determines the compensation level that can be achieved. If your winch has a maximum line speed in the range of 50 to 80 m/min, it will be possible to compensate for 3 – 4 m vessel motion, which is sufficient for most AHC applications.

Need help evaluating your winch for AHC?

Find out how much motion your system can compensate for, based on just a few key parameters.

Estimate how much vessel motion your winch can handle

Get results based on just a few key parameters

Get expert feedback from our team

Free of charge, no commitment required

Scantrol AHC Analyzer is trusted by system integrators and OEMs worldwide. Quick response. No obligations.